Epoxy flooring marks a breakthrough with its attractive, strong, long-lasting surface. First of all, though, before starting epoxy, you definitely should get the concrete ready. A poorly done surface could lead to peeling, bubbling, and a weak bond, compromising your investment.

Whether you are rebuilding your garage, cellar, or business, this article will walk you through the fundamental processes—cleaning, repairing, and etching—to ensure your epoxy adheres precisely. Following these rules will result in a lifetime’s worth of professionally graded work!

Let’s take a deep look at how to prep concrete for epoxy and resin flooring Brisbane.

What Makes Epoxy the Best Choice for Concrete Floors?

Among the best choices for concrete flooring is epoxy because of its strength, flexibility, and attractive appearance. If you’re wondering how to prep concrete for epoxy and why it stands out:

1. Excellent Resilience:

Epoxy’s tough, long-lasting surface resists machinery, high foot activity, and impact. For commercial buildings, warehouses, and garages, it’s ideal.

2. stain and chemical resistance:

Unlike bare concrete, which absorbs oil, grease, chemicals, and spills, epoxy is perfect for both domestic and industrial use.

3. Easy and Fast for Cleaning:

Resin flooring brisbane is smooth, nonporous quality helps to reduce dust accumulation and makes cleaning simple using just a mop or light detergent.

4. Attractive Attractiveness:

With its myriad colors, treatments, and ornamental choices—metallic or flake designs—epoxy can enhance the look of any room. Durable and rather cheaply priced epoxy permits concrete floor life to be extended, reducing maintenance and repair expenditures over time.

5. Moisture and Slip Resistance:

Epoxy coatings, made of slip-resistant chemicals, are a safe choice for wet or heavily trafficked surfaces.

6. UV and Heat Resistance:

Many epoxy formulas, being UV light and high temperature resistant, stop discoloration and degradation over time.

Because of its unmatched durability, low maintenance, and customizable look, epoxy is the perfect solution for concrete flooring in homes, garages, and offices.

The Benefits of Epoxy Concrete Flooring

Epoxy concrete floors gain favor in domestic, corporate, and industrial settings due to strength, longevity, and attractiveness, among other things. Here are some things they are distinguished for:

- Especially strong: Epoxy materials form an extremely strong surface that withstands severe foot traffic, machinery, and impact, making them ideal for garages, warehouses, and manufacturers.

- Chemical and stain resistant: Great for industrial activities, labs, and offices, thereby standing oil, grease, and chemical spills.

- Low upkeep, Easy to clean: Smooth surface, nonporous, so dirt, dust, and germs can’t find their way onto it.

- Added Safety: Epoxy flooring can enhance safety by incorporating slip-resistant modifications to reduce the accidents that may arise in an oversaturated or wet area.

- Attractive and customizable: Various colors, patterns, and finishes metallic or flake designs enhance the elegance of epoxy floors.

- Water and Moisture Resistance: Epoxy is moisture resistant, unlike pure concrete, which can help prevent water-related destruction in garages, basements, and industrial environments.

- Affordable and durable: Epoxy adds more value to the concrete floor, thereby extending its lifetime and saving the costs of repeated repairs and replacements, which are an invaluable investment.

- UV-resistant and resistant to heat: Many epoxy coatings offer long-lasting durability because they resist heat and won’t fade or discolor due to UV rays.

- Environmentally friendly replacement: Epoxy will not require tedious cleaning agents to abstract due to the fact that they can be cleaned easily and do not produce dust, creating a healthy indoor environment.

- Short installation and curing time: For sure, the biggest plus for people considering an elegant and long-lasting flooring solution that’s still pretty low maintenance, epoxy concrete flooring is ready to install fairly quickly and cures quickly, for homes and businesses alike.

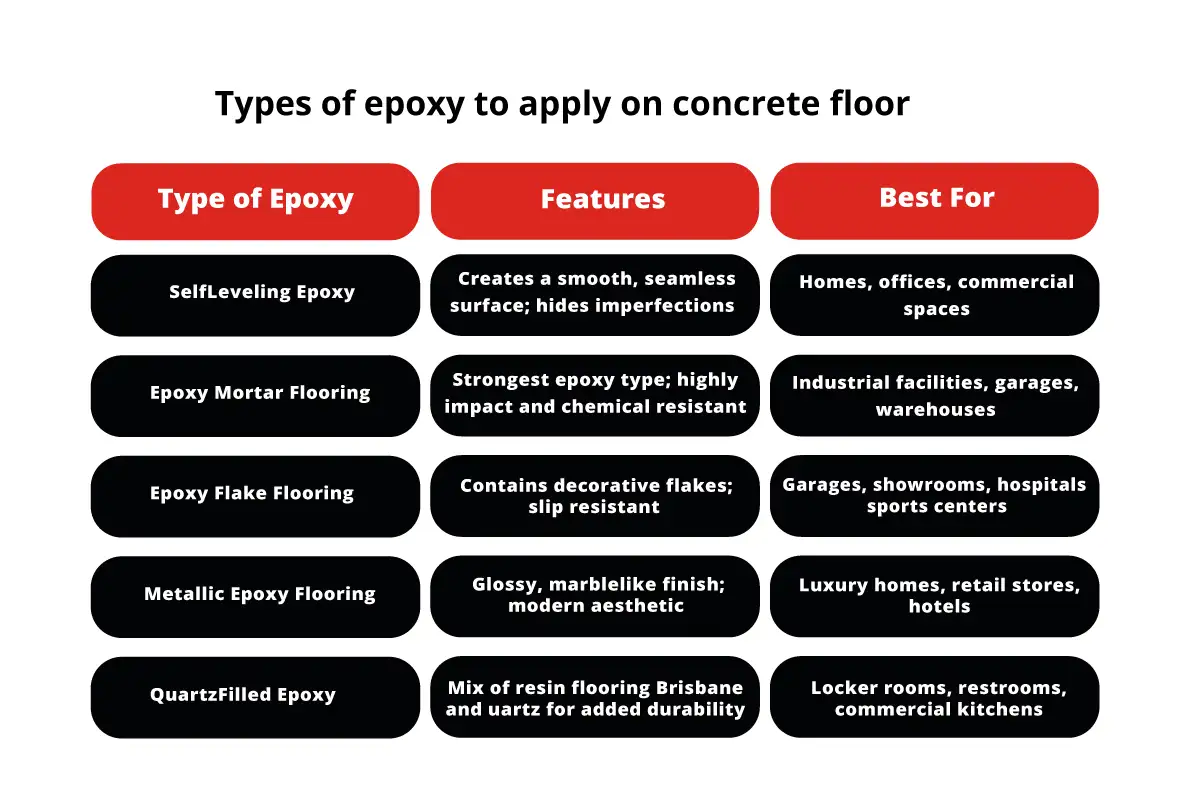

Types of epoxy to apply on concrete floor

The answer to the “How to prep concrete for epoxy” question is here! Coatings come in various types, each designed for specific applications. Below is a table outlining the different types of epoxy flooring, their features, and ideal uses.

Each type of epoxy provides unique benefits, making it essential to choose the right one based on your needs and environment.

Resin Flooring in Brisbane

Resin flooring is a popular choice in How to prep concrete for epoxy in Brisbane city for both residential and commercial applications due to its durability, aesthetic appeal, and ease of maintenance. Here’s an overview of resin flooring, its benefits, and common applications in Brisbane:

What is Resin Flooring?

Resin flooring is a seamless flooring solution made from a mixture of resin and hardener. It creates a strong, durable surface that can be customized in various colors, textures, and finishes. We wrote below How to prep concrete for epoxy to find out resin flooring Brisbane benefits:

- Durability

- Seamless Finish

- Easy Maintenance

- Water and Stain Resistance

How to prep concrete for epoxy: step by step

Correct preparation of your concrete floor will result in a robust, long-lasting epoxy finish. Use these guidelines to guarantee the epoxy develops a smooth, self-finish and is well adhered.

First: sweep the concrete surface:

Suggesting a degreaser or concrete cleaner in the guide of how to prep concrete for epoxy: clear all dust, filth, oil, and grease. To clear the trash, give the floor a sweep-through or vacuum. Should extensive cleaning be needed, run a pressure washer.

Second: fix holes and cracks:

Concrete patching materials or epoxy fillers allow one to cover cracks, gaps, and flaws. Let the patch cure; then, sand flat.

Third: hunt for moisture

Let a 2×2 sq. ft. plastic sheet you have laid flat on the floor stay for 24 hours. Should water gather under it, the concrete should have a vapor barrier built down before epoxy application.

Fourth: etch the concrete—if you are not grinding it

Stir an etching solution with the necessary water (such as muriatic acid or a commercial etcher). Cover the concrete with a sprayer or brush, then let it work. Under clean water, wash well; then let it dry totally. Should one be using a grinder, halt here and begin grinding.

Fifth: ground the floor (for best results)

Rough the surface mechanically with a diamond grinder or shot blaster. This stage serves to open the concrete surface’s pores, enabling appropriate bonding. After grinding, make sure you vacuum every bit of dirt and trash.

Sixth: last cleaning and drying

Clear the surface of any last dust using a moist mop. Before laying epoxy, let the floor completely dry. (usually in 24 to 48 hours).

seventh: Prime, Optional yet advised

Primers increase the endurance of your epoxy finish and help adhesion to be better. Use enough to create a base coat; let it cure per manufacturer’s recommendations.

Evaluating the concrete surface

Testing the surface is important. This is what directly influences adhesion and prevents common failures like peeling and bubbling. Hence, for checking out the concrete, do this:

Check for Contaminants

- Look for things such as oil stains, grease, and chemicals that hinder adhesion.

- The water drop test: pour water onto the surfaceIf the water beads up and doesn’t get absorbed, contaminants are present.

- Use a degreaser or a concrete cleaner as needed.

Inspect for Cracks, Chips, and Damage

- Small cracks and holes can be filled with an epoxy filler or concrete patch.

- Larger structural cracks may require professional repair.

- At the time of epoxy application, uneven spots should be evened out.

Test for Moisture

- High moisture levels can lead to peeling or bubbling of the epoxy over time.

- Plastic sheet test: Tape a square foot plastic sheet onto the floor for about 24 hours. If enough condensation or moisture collects under it, the concrete may have moisture problems.

- For accurate results, check the moisture levels inside the concrete by using a moisture meter.

Assess the Surface Hardness

- Soft or weak concrete may not hold epoxy well.

- Perform a scratch test: take a screwdriver or a coin and scratch your surface minded: if the concrete is crumbleprone, it probably needs strengthening or resurfacing.

Check for Surface Smoothness and Porosity

- Concrete that is too smooth (for example, power troweled floors) may hinder the chemistry of epoxy bonding.

- If the concrete happens to be sealed, etching or some sort of mechanical grinding needs to open those pores so the epoxy can bite in.

Once the concrete passes these evaluations, the next step will be surface preparation, cleaning, repairing, etching (or grinding), and priming to get the epoxy to adhere and perform well for so many years.

Can we apply epoxy to wet surfaces?

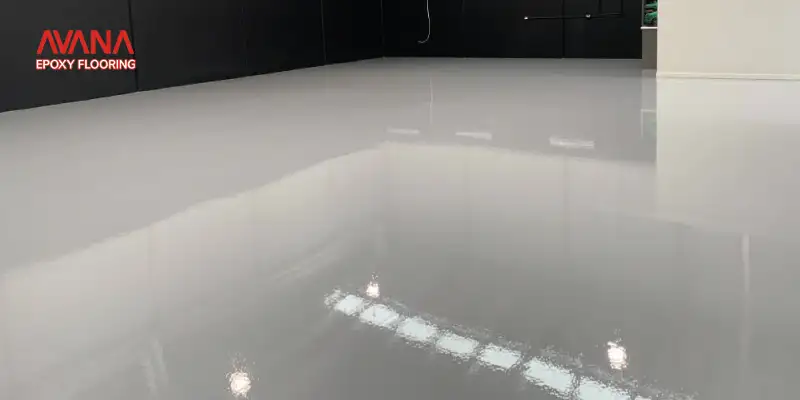

AVANA is perhaps the most original and unique of all epoxy systems and epoxy materials, capable of serving even the most challenging installations of wet floors.

AVANA Epoxy Flooring is one of the best suppliers of resin flooring Brisbane and Australia, providing quality epoxy flooring solutions. With more than ten years of experience, they specialize in the installation of both durable and beautiful-looking epoxy flooring applicable to all sectors, from residences to businesses.

Services Offered by AVANA Epoxy Flooring

- Residential Epoxy Flooring: Add-on to your home, happening seamless easy-clean surfaces with infinite colors and finishes.

- Commercial Epoxy Flooring: Robust flooring solutions for showrooms, restaurants, and retail spaces to stand heavy traffic and spills.

- Industrial Epoxy Flooring: Top-end flooring that doesn’t bubble, crack, and peel; industrial spaces like warehouses, factories, and workshops.

Why Choose AVANA Epoxy Flooring?

There are so many reasons for choosing AVANA Epoxy Flooring. Let’s take a deeper look at How to Prep Concrete for Epoxy:

- Ten years of experience: Experience in installation and conveying care to its customers are guaranteed.

- Quality Material: Quality, special industrial-grade materials are the dif-fix for durability.

- Customization: Extensive color, pattern, and finish options allow for virtually any custom flooring design.

- Safety and Maintenance: Stain-resistant, easily cleaned, and can be made slip-resistant by the addition of a slip-resistant additive.

Let anyone seeking a fusion between functionalism and stylishness know that AVANA Epoxy Flooring practically attends to their floors.

Final Thoughts

In conclusion, understanding how to prep concrete for epoxy is essential for achieving a flawless and durable finish. Proper cleaning, repairing, and etching of the concrete surface ensures optimal adhesion of the epoxy, preventing future issues like peeling or bubbling.

If you’re considering resin flooring Brisbane, look no further than AVANA Epoxy Flooring. With their expertise in epoxy installation and commitment to quality, AVANA offers tailored solutions that enhance the beauty and durability of your floors.

By following the right preparation steps and choosing a trusted provider like AVANA, you can enjoy a stunning and long-lasting epoxy floor that meets your needs and withstands the test of time.

FAQ

Five most often asked questions (FAQs) on how to prep concrete for epoxy regarding the concrete preparation for epoxy follow here:

1. Why should concrete be prepared before epoxy application?

Good preparation guarantees proper adhesion of the epoxy to sure surfaces; peeling, bubbling, or an uneven finish will not occur this way. It also extends the lifetime and resistance of the epoxy coating.

2. With what instruments should I prepare the concrete for epoxy?

These might comprise a trowel or putty knife to fix fractures, a concrete grinder or etching solution for surface preparation, and a pressure washer or broom for cleaning. Safety tools such as gloves and goggles also abound.

3. How can I find if my concrete is overly wet for epoxy?

The plastic sheet test lets you check for moisture: attach a clear plastic sheet to the concrete and leave it for 24 hours. Should condensation develop under the sheet, you have a moisture issue and could have to provide extra time for drying or install a vapor barrier.

4. Can I lay epoxy over existing concrete?

Epoxy can be used to coat old concrete if it is structurally sound and your only concern is the surface look. Repair holes, cracks, or any other surface flaw; clean it; and finally, arrange appropriately for adhesive fittings.

5. How long should I wait to apply epoxy once the concrete has been cleaned and etched?

The period between cleaning and etching and epoxy application is generally 24 to 48 hours. Above all, ensure it is totally dry before adding the epoxy to get the desired effects.